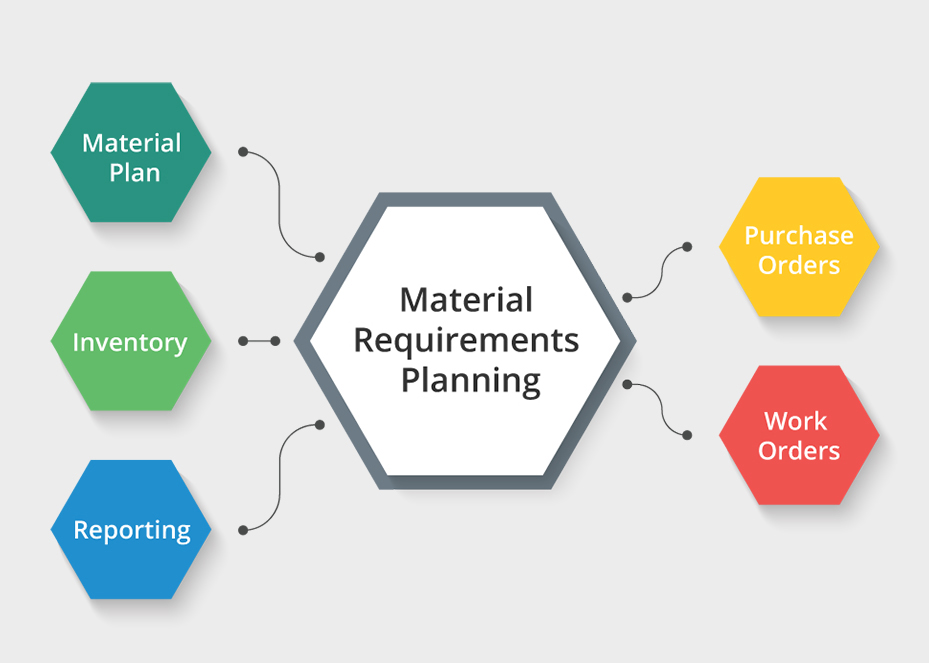

Material Requirement Planning is a mechanism which helps manufacturing firms to calculate Net requirement of material, material requirement time and most optimum Quantity of material.

Material Requirement Planning consists of following essential steps:

- Master Production Schedule (MPS): MPS is a set of phased amounts for each item that a business manufactures, showing how many are to be manufactured and when. MPS is initially built from firm customer orders or demand estimates before the MRP program starts to work.

- Bill of Materials: BOM includes information about components, components quantity needed and sequence of the process which will be used to build the end product. Information about work centres use for operations to produce end product is also included in BOM(Bill of Materials)

- Inventory status file: Inventory status file is file keeps all the record about the inventory of components, component identification number, quantity in hand, the quantity which already available, procurement lead time for each end product.

Based on the above-mentioned inputs, firms will work on:

- Planned order Receipts: According to demand generation in the market company decide their plan how much quantity they need to produce and for that one future receipt is generated which is known as planned order receipt. It is merely temporary receipts.

- Planned order Release: That is the order quantity of an item that is expected to be delivered during the timeline for this order, which will ensure that the item is issued as appropriate. The planned release of the order shall be decided by offsetting the planned receipt of the order by the time of the delivery of that item.

- Order Rescheduling: Rescheduling of orders happen in case of unexpected situations. In cases of order cancellation due to sudden demand drop in the market.

Benefits of MRP:

- Inventory level Regulation

- Customer service betterment

- Flexible enough to handle changes in demand

- Set-up cost and product changeover cost optimization possible

- Efficient usage of machinery

- Increased sales and a reduction in sales price.

Material Resource Planning -II

Manufacturing Resource planning (MRP-II) is an extension of MRP. MRP-II required for capacity planning, shop floor controls, scheduling every operation and other calculations. MRP-II includes comparison of forecasting and actual sales data so firms able to analyse their performance and can work upon the efficiency of their Manufacturing Resources.

Benefits of MRP II

- Improvement in on-time completion.

- Inventory cuts and better customer service.

- Data gathering possible for future planning purpose.

- Increase in Direct labour productivity

- Production can be prioritised properly.

Read other concepts: